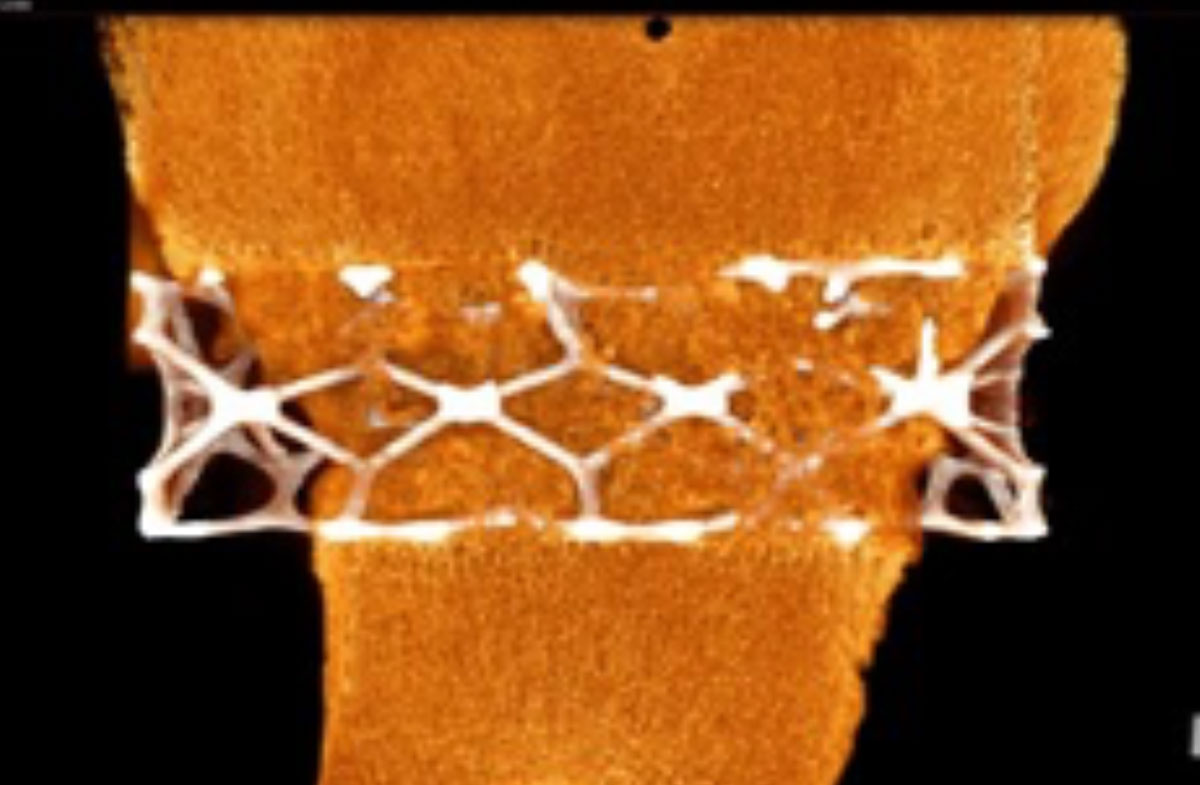

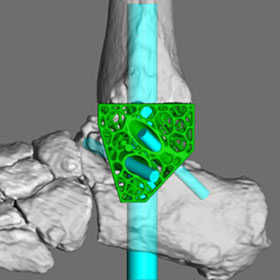

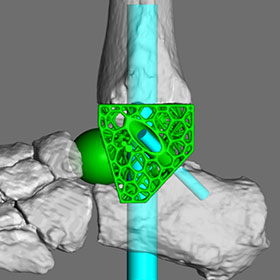

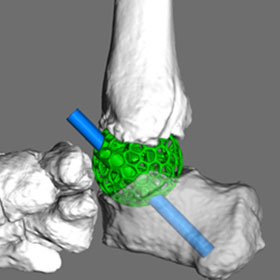

Patient-specific Custom Talus Spacers (CTS) are additively manufactured implants that are used in talus replacement surgery. The Custom Talus Spacer is made for each patient individually, is modelled from computed tomography (CT) imaging, and is fitted to a patient’s specific anatomy. The Talus Spacer is a fully-articulating talus replacement which allows patients to retain full movement. It is a solid, fully polished implant that does not fuse with surrounding bone.

The CTS implant is made of solid titanium alloy (Ti-6Al-4V) and replicates the biomechanical function of the talus. The major articulating surfaces to surrounding bones (Tibia, Calcaneus, Navicular) are recreated as required. The structure is designed to replicate patient anatomy, while minimising small cavities (with high radius of curvature). The implants are highly polished and coated with Titanium Nitride (TiN) to improve wear resistance and articulation.